Dongguan XinHuizhan Electromechanical Co., Ltd. was founded in 2005. It is a technology-focused manufacturer specializing in the R&D, production, and integration of micro motors and drive modules. The headquarters is located in Dongguan, China, and in 2025, a Taiwan branch was established to expand local services and sales presence across the APAC region.

With over twenty years in the micro motor industry, the company has more than 220 employees, including 15 R&D engineers and technicians and 18 quality management staff, with stable production capacity and strong in-house technical development capabilities.

We are certified under IATF 16949:2016 and ISO 14001. From product design and prototyping to mass production and delivery, we have implemented systematic, standardized process controls to provide reliable, efficient, and customized drive solutions to customers worldwide.

XinHuizhan products are widely used in automotive, home appliances, power tools, smart devices, medical equipment, and energy-saving fans. They mainly include the following:

• Micro Motor Products:

DC motors, brushless motors, induction motors, automotive motors

• Gear and Drive Modules:

Planetary gearboxes, worm gear reduction modules, integrated solutions for metal/plastic gearboxes

• Motor Accessories and Control Units:

Drivers, control boards, encoders, Hall sensors, motor end caps, brackets, connectors, etc.

We also offer ODM/OEM development services and can provide customized motor design and system integration for end applications, helping customers bring products to market quickly.

We have an in-house development team capable of rotor design, coil winding, structural design, and finished product testing, allowing for both electrical and mechanical optimization according to customer requirements.

Our core manufacturing capabilities and equipment include:

• Automated and semi-automated winding and assembly lines

• Gear module processing and assembly

• Induction motor production lines

• Injection molding (investment in Qingxi Yunsheng Electric to integrate plastic part production)

• Stamping parts, mold development, and small-batch prototyping support

• Encoder/control board assembly capabilities

From the motor itself to accessory supply, we offer a highly integrated one-stop production solution.

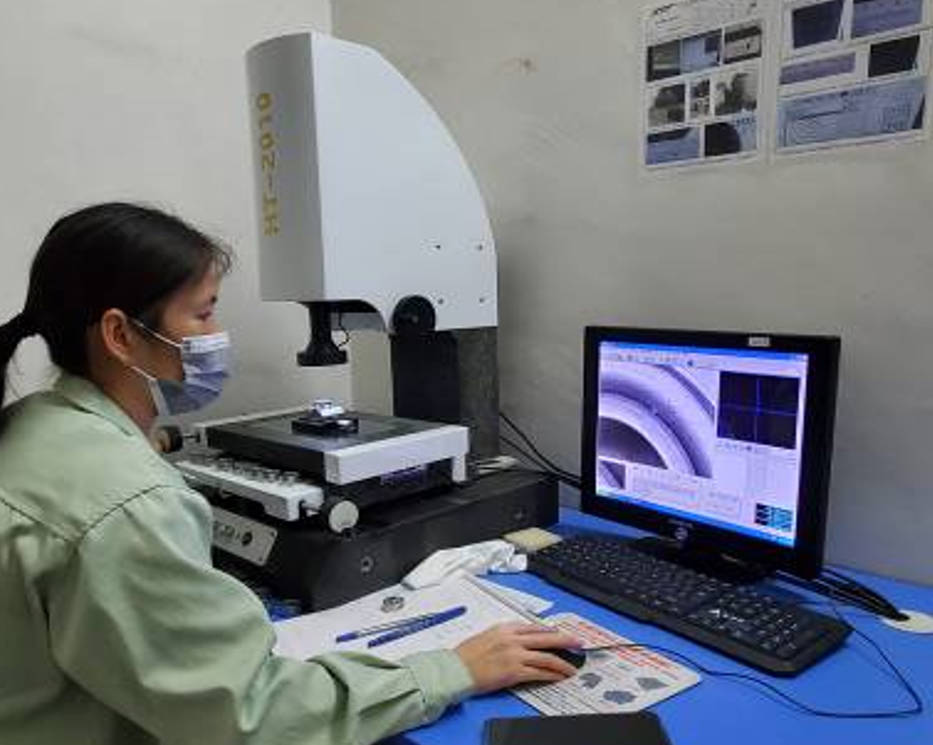

XinHuizhan always adheres to the principle of "quality first, stability as the foundation" and has established a full-process quality control system, including:

• Incoming Quality Control (IQC)

• In-Process Quality Control (IPQC)

• Final Quality Control (FQC) and Outgoing Quality Control (OQC)

• Long-term lifespan and high/low temperature testing

• Full or sample inspection of key indicators such as motor dynamic balance, noise, start voltage, and load performance

All processes are executed according to TS16949 standards and supported by ERP and document traceability systems to ensure batch control and consistent product quality.

We believe that quality, efficiency, flexibility, and integrity are the keys to long-term cooperation. Moving forward, XinHuizhan will continue to enhance technological innovation and industry integration capabilities, growing together with global customers and driving every advancement in micro power.

Integrity in Collaboration · Lean Manufacturing · Driving Innovation Forward